Energy Research Lab Lab Members Projects

Current and Past Research Projects:

Liquid Biofuel Fischer Tropsch Synthesis from CO and H2 – Steve Wirya, Gustavo Mancini, Brian Noland, Steven Wong, Aneesh Rege

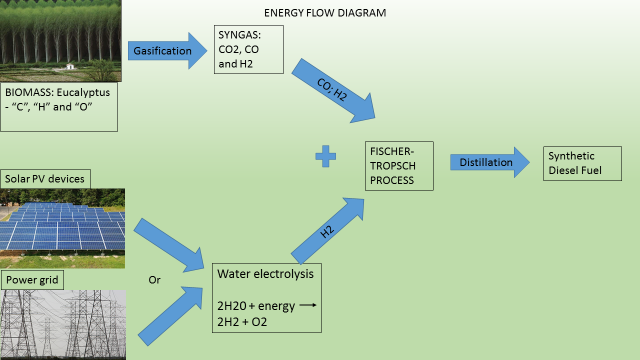

For many years the laboratory has investigated hydrogen production via reformation of liquid fuels. We have discovered and developed advanced methods of heat and mass transfer enhancement for these applications. We are currently broadening our expertise in reformation to bear on fuel synthesis methods, such as in Fischer-Tropsch fuel synthesis, that are similarly limited by heat and mass transfer. The successful implementation of heat and mass transfer enhancement potentially allows realistic biofuels to be used as gasoline and diesel replacement fuels. We are currently seeking funding to support our work in understanding how Fischer-Tropsch fuel synthesis can be changed by use of our heat and mass transfer enhancement methods. A very simplified top level view of the  processes is shown below for creating synthetic diesel using a biomass feedstock.

processes is shown below for creating synthetic diesel using a biomass feedstock.

Thermochemical Recuperation of Exhaust Heat – Isaac Silva,

Low NOx Engines can be enabled by harvesting exhaust heat from the engine to upgrade a hydrocarbon fuel to a ![IMG_2405[1]](https://faculty.engineering.ucdavis.edu/erickson/wp-content/uploads/sites/58/2013/02/IMG_24051-e1393449461549-300x225.jpg) hydrogen -rich mixture subsequently allowing simultaneous efficiency increase and emissions decrease in the engine. We have operated small engines in open-loop with a hydrogen mixture (see past work by Eddie Jordan, Jason Greenwood, Ryan Gemlich and Fethia Amrouche) and creation of a hydrogen mixture from simulated exhaust and fuel (see past work by David Vernon and others). These past projects culminated in Isaac Silva’s work operating a small engine from methane while harvesting a portion of the exhaust to enable hydrogen injection into the intake in a closed loop fashion. Significant exhaust heat is captured in this process and changes to the engine operation by utilizing the hydrogen created can occur in a stable manner. These results indicate that thermochemical recuperation of exhaust heat can be practically used to increase efficiency and reduce emissions in the spark ignition engine.

hydrogen -rich mixture subsequently allowing simultaneous efficiency increase and emissions decrease in the engine. We have operated small engines in open-loop with a hydrogen mixture (see past work by Eddie Jordan, Jason Greenwood, Ryan Gemlich and Fethia Amrouche) and creation of a hydrogen mixture from simulated exhaust and fuel (see past work by David Vernon and others). These past projects culminated in Isaac Silva’s work operating a small engine from methane while harvesting a portion of the exhaust to enable hydrogen injection into the intake in a closed loop fashion. Significant exhaust heat is captured in this process and changes to the engine operation by utilizing the hydrogen created can occur in a stable manner. These results indicate that thermochemical recuperation of exhaust heat can be practically used to increase efficiency and reduce emissions in the spark ignition engine.

Stratified Reformation – Nadia Richards, Edgar Necoechea

In hydrogen steam-reformation systems, mass flow throughputs are relatively small which typically requires multiple tubular reactors in parallel to obtain high flow rates. In autothermal reformation the mass flow rates are relatively high but gas quality is typically much lower than steam reformation methods. In many applications volume must be minimized and maximum flow rate and high gas quality is desired. In order to increase mass flow in a reactor  while maintaining high gas quality we are investigating the idea of short catalyst contact time. We introduce the fuel/reactant mixture on a specifically designed catalyst to break apart reactants with an exothermic step then immediately reassemble the desired molecule on a highly-selective endothermic catalyst in a single tube. This two step process is what we are terming stratified reformation where two catalysts are used in series to maximize flow rate and simultaneously increase output gas quality. Preliminary results indicate that this technique yields the benefits of autothermal reformation in mass flow rate with outgas purities approaching that of steam reformation. Previous thought was that low temperature WGS catalysts could not be used in this manner and our studies indicate that longer chain fuels may be able to be processed to high quality hydrogen in a similar manner. Studies are continuing with various fuels being investigated.

while maintaining high gas quality we are investigating the idea of short catalyst contact time. We introduce the fuel/reactant mixture on a specifically designed catalyst to break apart reactants with an exothermic step then immediately reassemble the desired molecule on a highly-selective endothermic catalyst in a single tube. This two step process is what we are terming stratified reformation where two catalysts are used in series to maximize flow rate and simultaneously increase output gas quality. Preliminary results indicate that this technique yields the benefits of autothermal reformation in mass flow rate with outgas purities approaching that of steam reformation. Previous thought was that low temperature WGS catalysts could not be used in this manner and our studies indicate that longer chain fuels may be able to be processed to high quality hydrogen in a similar manner. Studies are continuing with various fuels being investigated.

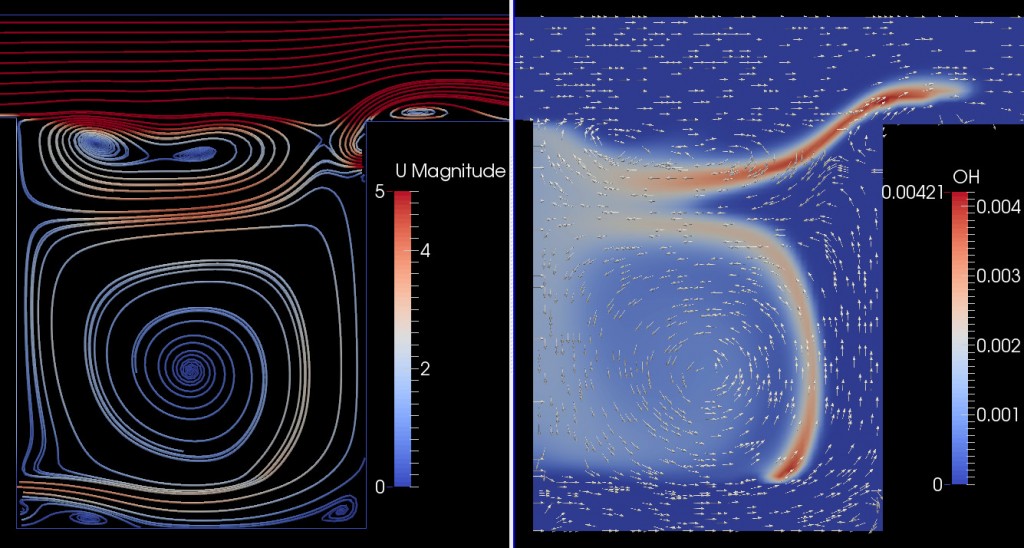

Endothermic Fuels and Hydrogen Bifueling for Gas-Turbines – Justin Hwang, Steven Wong

In aerospace gas turbine engines flame stability is critical to mission safety. Previous studies have indicated that hydrogen bifueling (hydrogen burnt in conjunction with another fuel) can stabilize such flames. Benefits of hydrogen bifueling extend to both energy efficiency and emissions reductions in the engine. Thermal NOx can be significantly decreased with hydrogen by allowing stable fuel lean operation. However promising, pure hydrogen  has significant energy density penalties which make onboard hydrogen storage an unlikely option for mobile applications. Hydrogen for mobile applications will most likely be created from higher energy density fuels using reformation techniques rather than be stored onboard in gaseous or liquid form. We are investigating how the created hydrogen-rich gas (called reformate) from high-energy density hydrocarbon fuels might stabilize a flame in a bifueled system.

has significant energy density penalties which make onboard hydrogen storage an unlikely option for mobile applications. Hydrogen for mobile applications will most likely be created from higher energy density fuels using reformation techniques rather than be stored onboard in gaseous or liquid form. We are investigating how the created hydrogen-rich gas (called reformate) from high-energy density hydrocarbon fuels might stabilize a flame in a bifueled system.

Furthermore, there are some multi-function fuels which can act as a heat sink and could potentially be used as endothermic fuels to cool critical engine components saving weight of auxiliary systems while simultaneously harvesting waste heat which will increase efficiency. When being heated most of the known endothermic fuels are susceptible to coke (solid carbon) formation which potentially blocks critical passages for fuel delivery. Typical fuel additives which inhibit this coke formation in endothermic fuels have also been shown to decrease flame stability. Increased flame stability through hydrogen or reformate can potentially counteract the coke inhibiting additives and enable practical use of endothermic fuels. We are investigating both endothermic fuel strategies and the flame stability of reformate mixed with endothermic fuels in order to potentially allow their use in gas turbine power systems without compromising flame stability and mission safety.

Acoustic Enhancement of Reacting Flows in Fuel Cell Applications – Siva Gunda

Parametric studies of Low-cost Pico-Hydro Power for rural applications- Kyle Gaiser

In many parts of the developing world, rural, and off grid applications, conversion of hydropower in small scale (pico-hydro <5kW)  is done suboptimally due to the high capital cost of commercially designed equipment. Many pico-hydro applications could be significantly benefitted by a better understanding of the fundamental parameters regarding hydropower conversion and the basic principles involved in the design, manufacture, and operation of simple turbines that could be constructed from readily available materials and construction methods. We have investigated the performance of a low-cost turgo-type turbine and have studied the main parameters affecting the power conversion thereof. Our overall goal is to allow a significant increase of energy conversion efficiency in low-cost turbines and thus allow better designs in the extraction of power for these types of applications.

is done suboptimally due to the high capital cost of commercially designed equipment. Many pico-hydro applications could be significantly benefitted by a better understanding of the fundamental parameters regarding hydropower conversion and the basic principles involved in the design, manufacture, and operation of simple turbines that could be constructed from readily available materials and construction methods. We have investigated the performance of a low-cost turgo-type turbine and have studied the main parameters affecting the power conversion thereof. Our overall goal is to allow a significant increase of energy conversion efficiency in low-cost turbines and thus allow better designs in the extraction of power for these types of applications.

Fuel Cell Cathode Air Filtration – Arjun Tejaswi

Aluminum Powered Hydrogen Production for Mobile Applications – Brian Noland and Karthik Ganesh

Modeling Heat Release in Hydrogen Enrichment – Eddie Jordan

Hydrogen Enrichment in the Spark-Ignition Internal Combustion Engine– Jason Greenwood

Retrofit and Testing of Fuel cell Motorcycles -Sanders and Jhaveri

Thermal Storage Integration with Refrigerators and Renewable energy via PCMs -Kornbluth

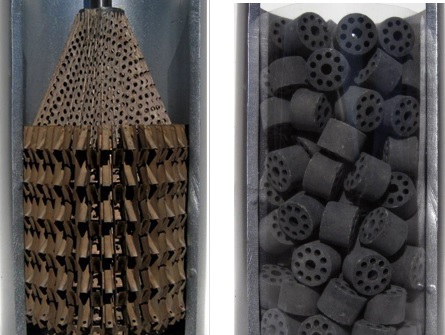

Heat and Mass Transfer Enhancement in Steam Reformation with Structured Catalysts– Ian Sit, Kevin Uy, Shalah Mammadova

International Energy Development-Gunda and Kornbluth

Hydrogen from Biofuels-ethanol and mixed alcohols – David Vernon

Hybrid reformation {ATR with low cost steam reforming catalysts} (theory, modeling, degradation, and transient following capabilities) – Hsu, Kasheveroff, Tang, Richards

Algorithms for Control of Reformers -Ray Tang

Catalytic Light off for Reducing Start up emissions-Todd Skinner, Anthony Montevirgen

Hydrogen Enriched Internal Combustion engines- Compression Ignition Engines -Will Marin

Bus (retro fit to IC Hybrid operation) Controls etc

Fuel Cell Bus Acoustics and Noise reductions from Heavy Duty Fuel Cell Vehicle Systems-Zachary Zoller

Reforming of Mixed Alcohols formed from Gasification Pathways– Matthew Caldwell